Infrastructure

Metal Casting

Design

Complete design software features powerful capabilities in solid modeling of components, assembly modeling, sheet metal design, freeform modeling, and convergent modeling.

Pattern & die

Manufacturing of the pattern and die by referring to the CAD model provided by the mold designer. CAM programming is done using Unigraphics CAM.

Sand Mould Production

Produce quality cores or molds using just enough binder to obtain the desired casting results at the lowest possible cost. Automatic continuous operations enable higher productivity and consistent quality molds and cores.

Metal Melting

Faster melt with uniform temperature distribution with electric resistance furnace. Degassing, grain refinement, and nucleation is done to improve the melt quality.

Heat treatment – T6

With controlled heating in specified time followed by water quenching is achieved fully automatically with solution heat treatment furnace.

Looking for a First-Class Scientific Partner?

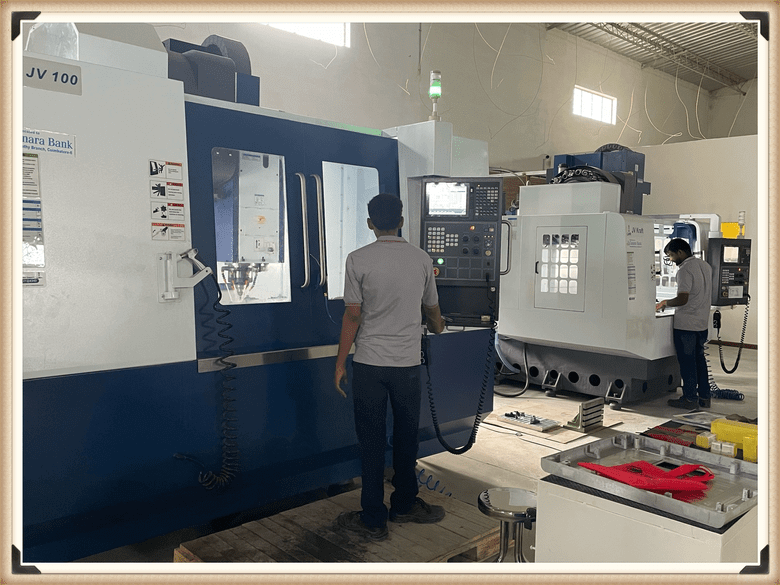

Machining

LMW JV-Kraft VMC

CNC vertical machining center from the LMW for manufacturing the parts with high accuracy, repeatability and consistancy.

LMW JV-100 VMC

CNC vertical machining center from the LMW for manufacturing the parts with high accuracy, repeatability and consistancy.

WorkNC – CAM

With 3 axis and multi-axis CAM programming capabilities, we are manufacturing the parts from solid billet materials, die and tools.

Milling Machine

General purpose milling machine helps in creating stock and raw material with rough near netshape material cost effectively.

Tool presetter

With the help of tool presetter, every tools being preset before employed for the metal cutting, ensuring high quality machining.

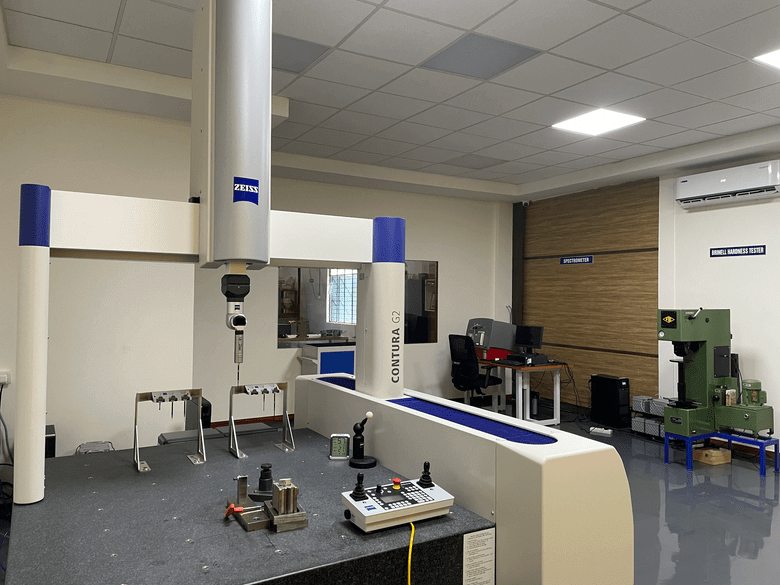

Quality Assurance

Zeiss ConturaG2 CMM

Reliable, high precision and repeatable measurement ensure all the parts are within the specified tolerances

2D Height Gauge

It offers expanded measuring possibilities with a very high level of user comfort. Thus the measurements in 2 coordinates, thus is accurate

Spectrometer

In-process metal chemical composition control with real-time testing results ensures every melt is in sync with the customer specification.

Hardness Tester

With hardness testing, the final quality of the part is established to verify the mechanical properties are matching the requirement.

Surface plate

With a large surface plate size 600 X 500 mm, the inspection process is ensured to be in stable and consistant.

Outsourcing

Vendor partners

.